EPDM RAW EDGE COGGED DEEP WEDGE V-BELTS

Overview

EPDM RAW EDGE COGGED DEEP WEDGE V-BELTS

Dynamic-X EPDM raw edge cogged deep wedge has a construction that exceeds the power transmission capability of standard deep wedge V-belts. They limit slippage and MegaMatch construction assures there is no need for belt set matching when used in multiple belt drives.

Features

- EPDM Compound: High Temperature and Flex Fatigue resistance with environmentally friendly properties

- Raw Edge Sidewalls: Saves energy by minimizing slippage with increased efficiency in comparison with wrapped v-belts

- Improved Cog Design: Increased flexibility and improved performance on small diameter pulleys and high speed drives

- MegaMatch Construction: All belts meet the tightest dimensional tolerances and can be installed without matching

- Heat Resistant: Better than standard belts in higher ambient temperatures

- Ground Sidewalls: For smooth-running operation with no vibration and reduced noise levels

- Environment Friendly: All compounds are halogen-free and RoHS compliant

- Static Conductive: Dynamic-X belts are static conductive according to ISO 1813 & ARPM IP3-3 standards

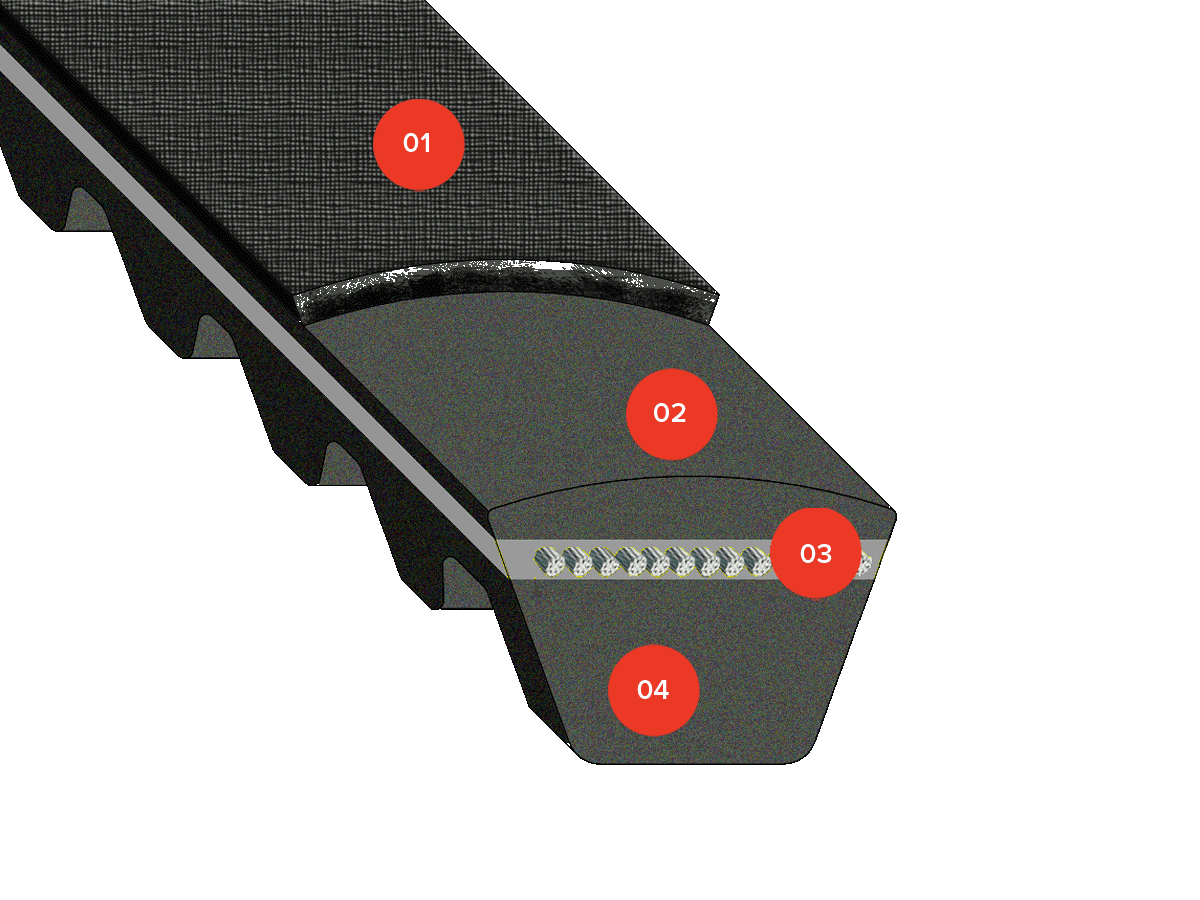

Main components

1 / Backside Fabric

Cotton/Polyester Blend

2 / Body

EPDM (XPC belts are Chloroprene)

3 / Cords

Polyester

4 / Improved Cog Design

Increased flexibility and improved performance on small diameter pulleys and high-speed drives

Mechanical and chemical properties

- Applications General Industry, HVAC equipment, pumps, blowers, high ambient temperatures, high efficiency drives and more

- Engineering Standards: Conforms to ARPM standard IP-22

- Temperature Range: -40°F to + 230°F (-40°C to +110°C)

- Recommended Pulleys: Use pulleys made to ARPM & MPTA standards

- Profiles: 3VX & 5VX