Fitness

Overview

The fitness industry is a fast growing sector. Around the world, OEM teams are striving to engineer stronger, quieter, and better performing products to meet the growing demands of their customer base. Through Megadyne’s Partner in Design program, our team works closely with customers to meet budgetary and performance criteria – taking into consideration our broad range of belt construction options, reinforcement types and manufacturing processes.

Grease-free, durable, smooth starting and running, silent operation and maximum efficiency even with reduced dimension: these features are a must. Additionally, every machine has its specific challenges, requiring peak load or power load capacity, a wide range of driven speed and much more.

Products

Many Customers are linked to Megadyne with this specific Industrial sector thanks to its wide range of standard and customized products; look forward our selection and choose the right solution for your specific application!

For an extended range of our Fitness belts, see the website of our sister company Ammeraal Beltech.

Success Stories

-

Trainer

-

Treadmill

-

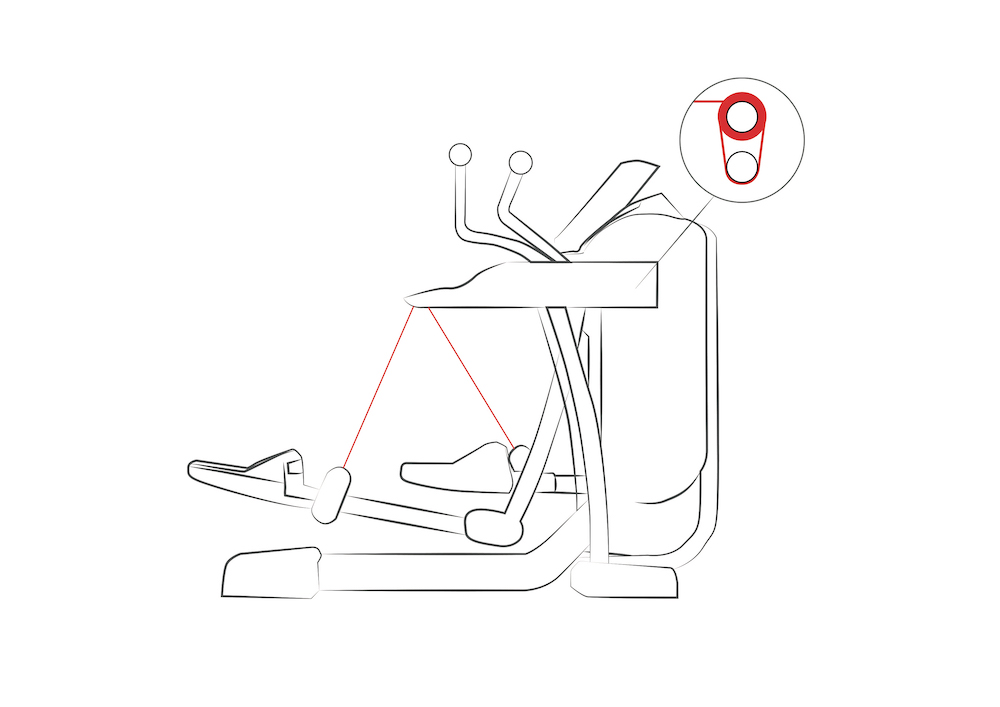

Trainer

Fitness centers and homes are filled with exercise equipment that must operate as quietly and smoothly as possible to provide the best possible user experience. An exercise equipment manufacturer was experiencing a belting challenge on the drive of a high end cross trainer they were developing for the fitness center market. The manufacturer tried chain, v-belt and timing belt drives, but all of the drives either caused too much noise or could not properly transmit torque. Download this success story to see how Megadyne solved the issue!

-

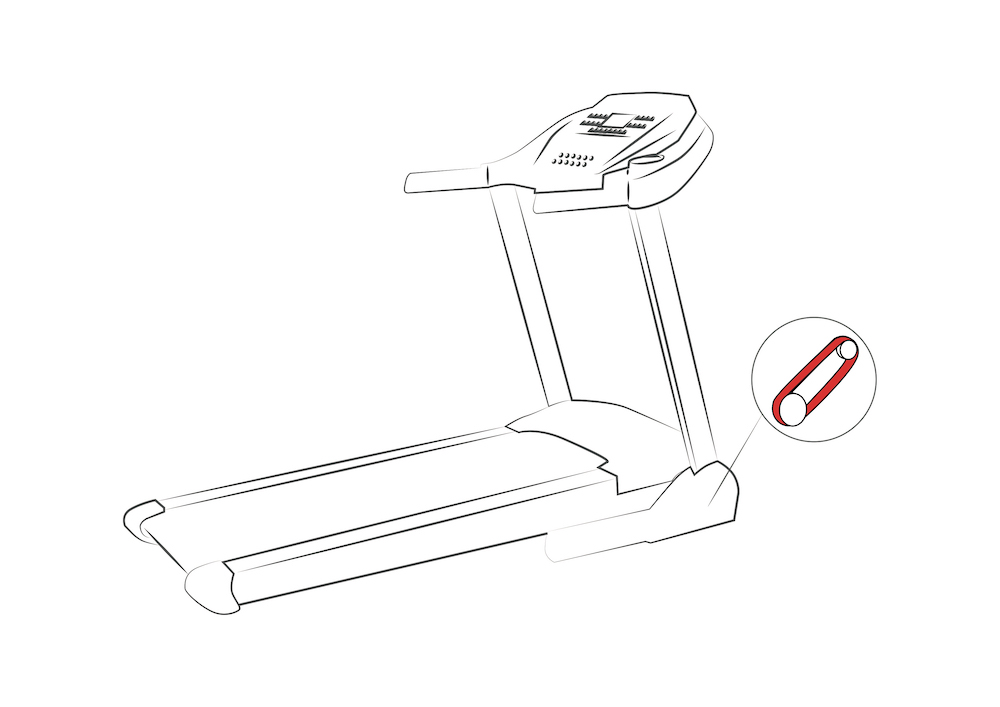

Treadmill

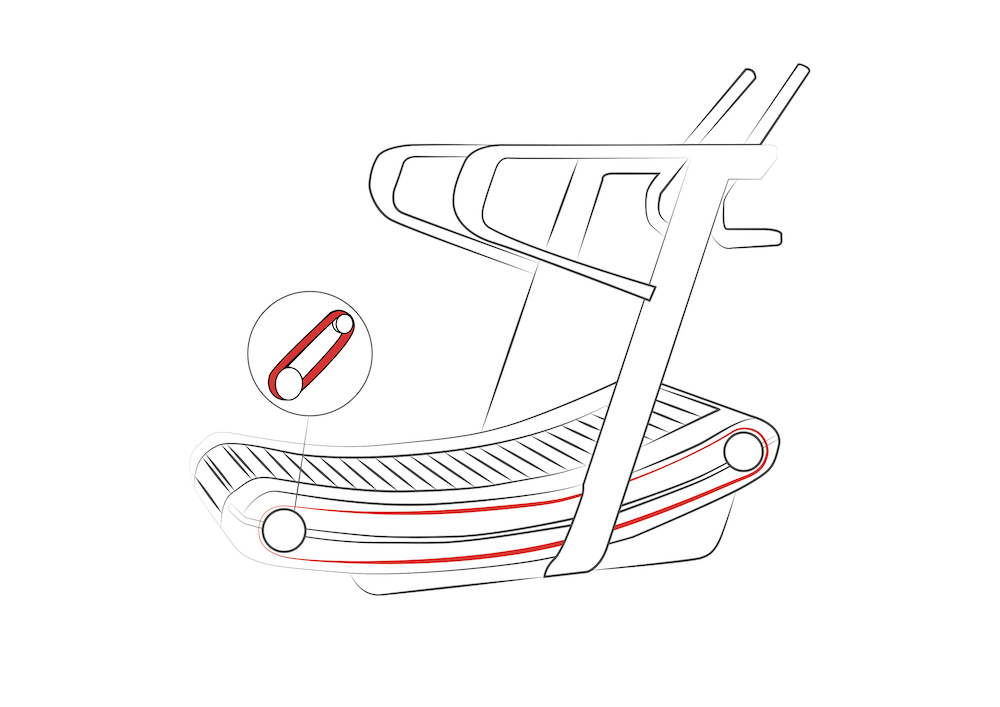

A manufacturer of high-end treadmills contacted Megadyne for assistance with drive issues on a treadmill they were developing for the elite athlete and medical rehabilitation segment of the fitness market. In this application, the slats that make up the conveyor belt are attached directly to the drive belts. The belts supplied by a competitor experienced various problems including drive noise and erratic movement required. There were also issues with the slats becoming loose and eventually detaching from the drive belts. Continue reading to see our solution!

Main Applications

-

Traditional Treadmill

-

Slat Treadmill

-

-

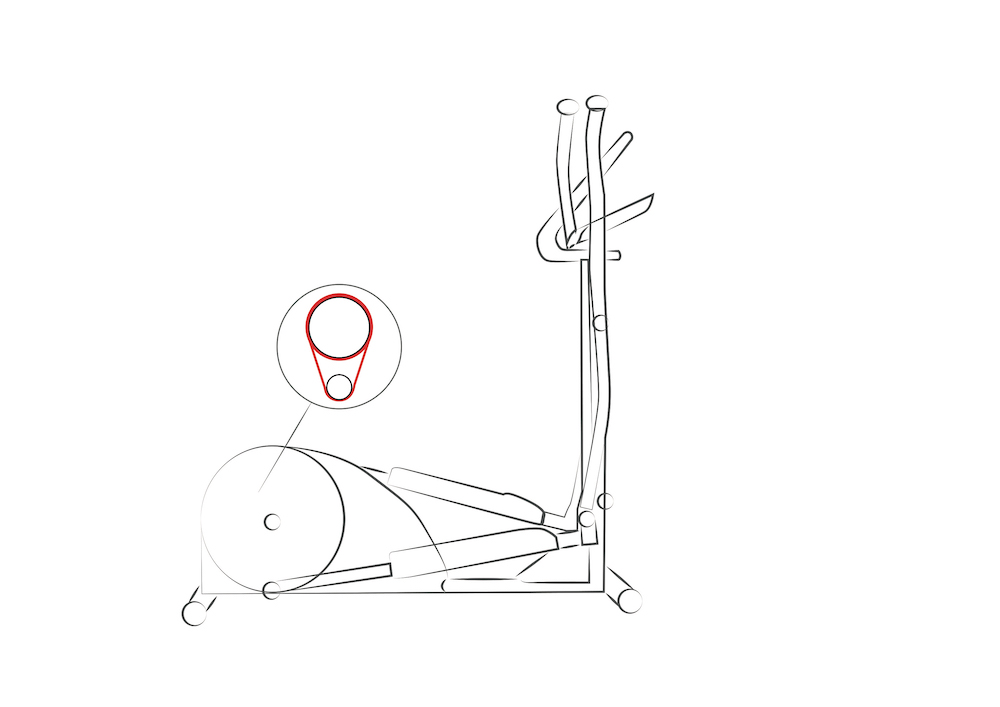

Elliptical Trainer

-

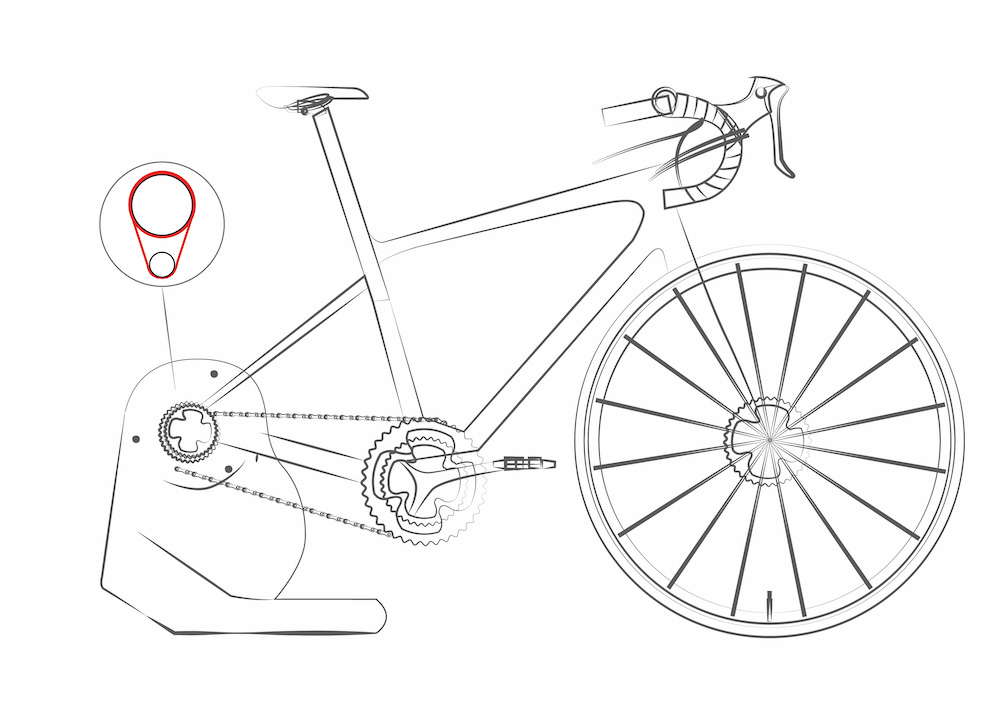

Bike Trainer

-

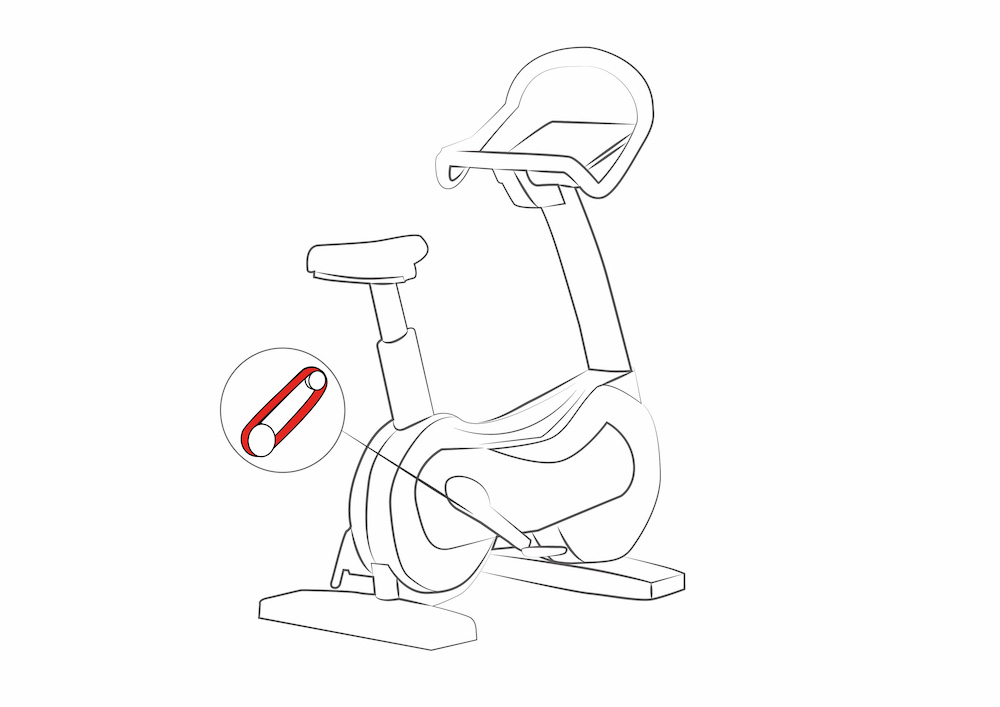

Exercise Bike

-

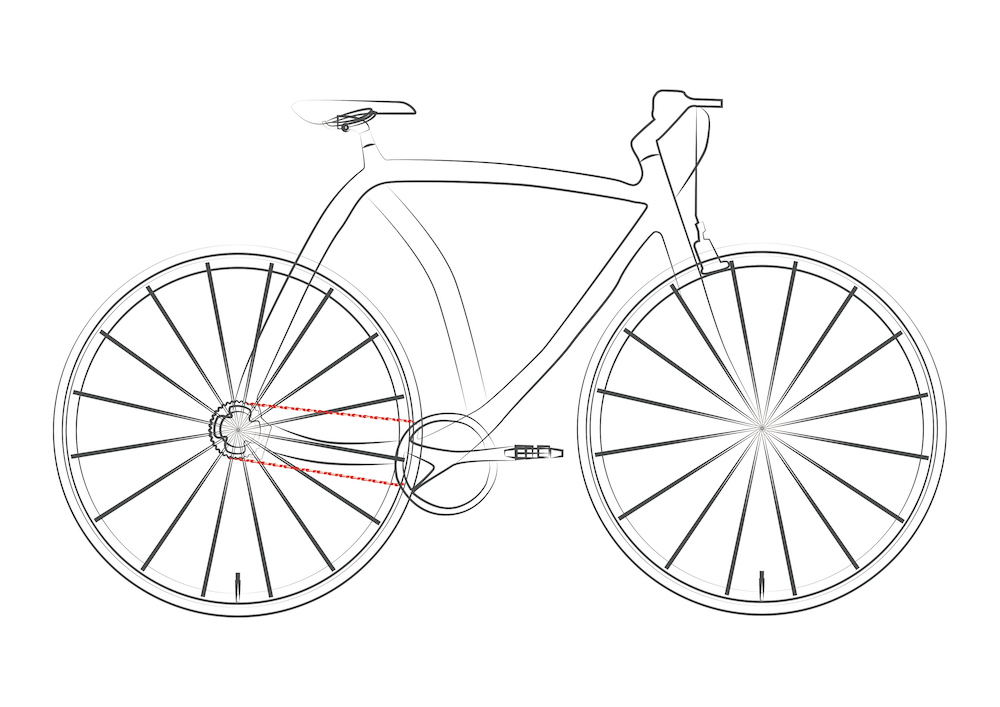

Bicycle

-

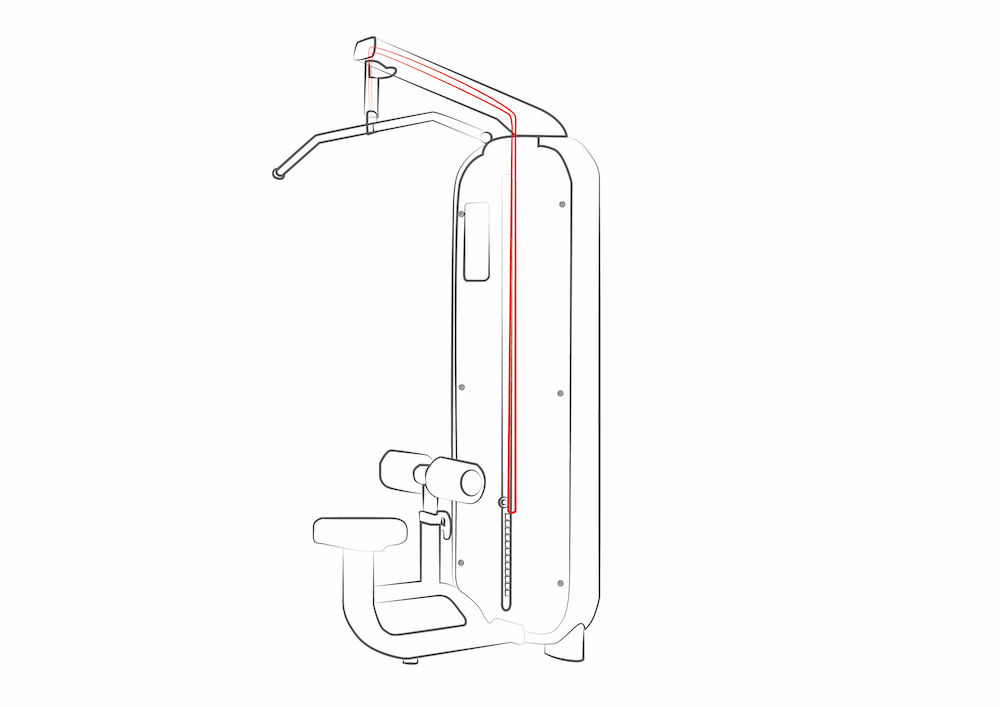

Weight Training Machine

-

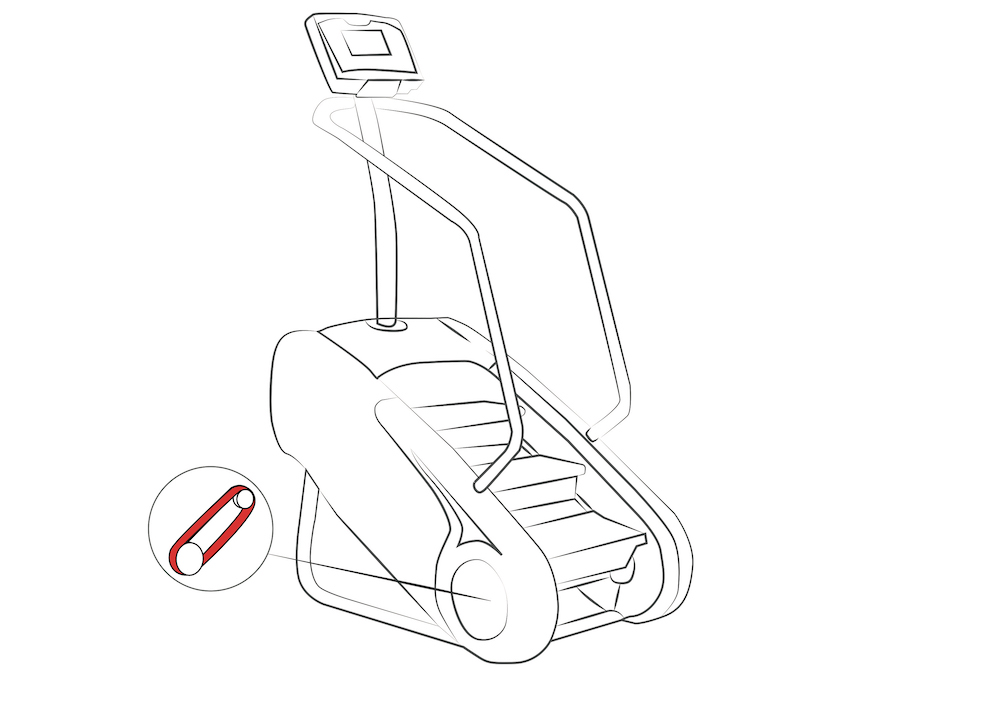

Stepmill