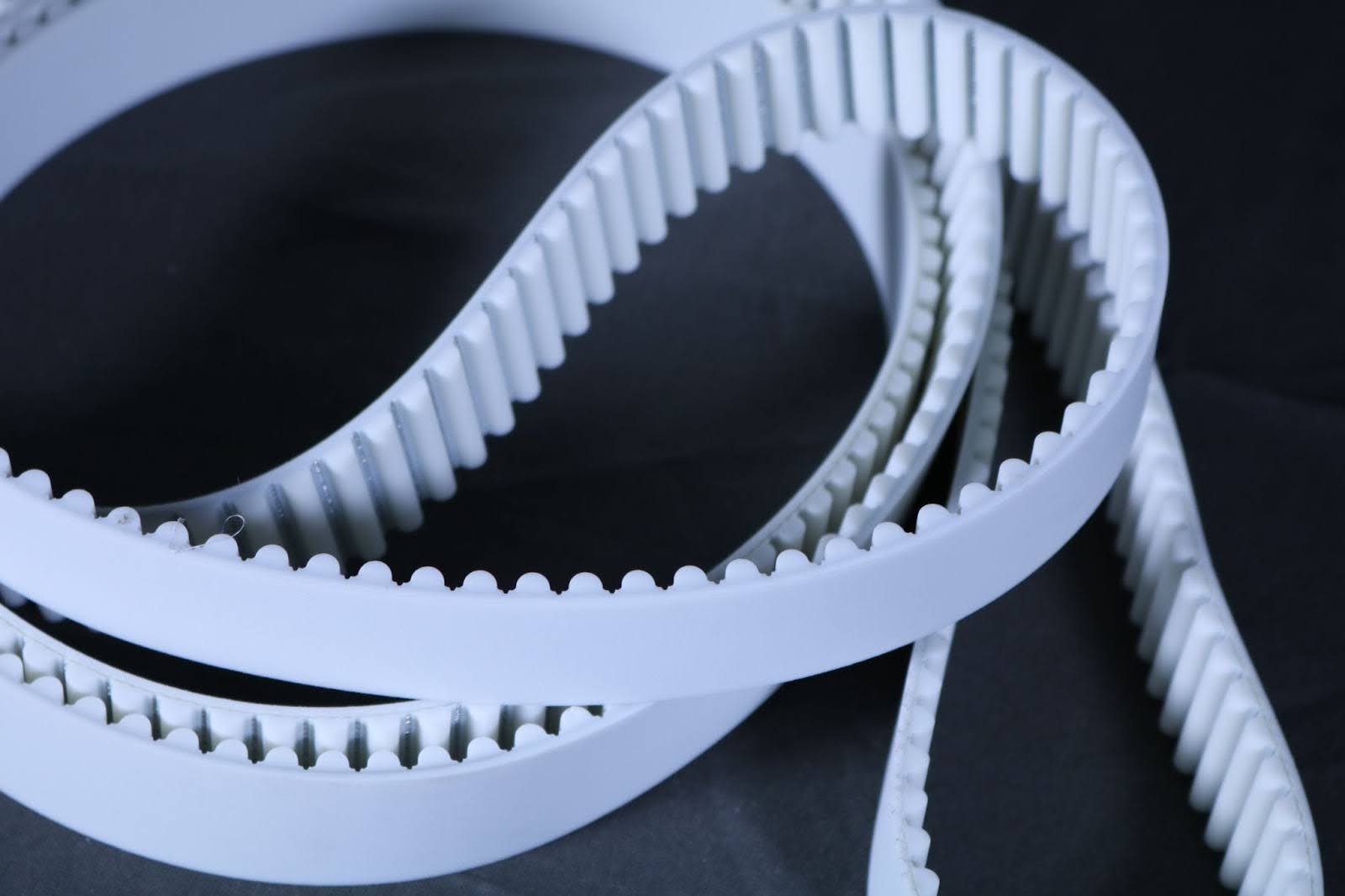

Polyurethane open-end timing belts, constructed from robust and resilient polyurethane material, offer a host of advantages such as wear resistance, chemical resilience, and precise synchronization, setting them apart from traditional timing belts.

These specialized belts find diverse applications, with a notable focus on linear motion systems in industries like 3D printing and CNC machining. Their use extends to the medical and pharmaceutical sectors for precise equipment operation and hygiene-sensitive environments, as well as in the food and beverage industry for moisture and chemical-resistant conveyance, highlighting their unique versatility and utility beyond conventional timing belts.

Key benefits of polyurethane open-end timing belts:

-

Superior Resistance: These belts exhibit remarkable resistance to water, oil, and grease, ensuring longevity and reliability in challenging environments.

-

Temperature Tolerance: Depending on the specific product, some polyurethane belts can withstand exceptionally high temperatures, often enhanced by the addition of materials like Kevlar, preventing material degradation.

-

Durable Against Wear: Polyurethane's inherent abrasion and impact resistance make these belts highly durable, reducing maintenance and replacement costs.

-

Flexibility and Elasticity: The material's flexibility and elasticity enable precise synchronization and smooth motion in various applications, enhancing operational efficiency and performance.

Polyurethane open-end timing belts find widespread applications in various industries, with notable use cases including:

Power Transmissions & Roller Conveyor Systems

Polyurethane's exceptional durability and resistance to wear and chemicals make it an ideal choice for power transmission belts, ensuring reliable and efficient energy transfer. For roller conveyor systems, polyurethane's robustness reduces maintenance and enhances the longevity of conveyor components.

-

Material Handling: Open-end polyurethane belts are widely used in material handling equipment, where they facilitate the smooth and efficient transfer of goods. Their resistance to abrasion and flexibility enable precise control in conveying systems.

-

Automated Warehousing: Automated warehousing systems, involving the movement of platforms up and down or side to side, benefit from open-ended polyurethane belts due to their reliability, precision, and durability, crucial factors in maintaining efficient warehouse operations.

When it comes to urethane timing belts for power transmission, the choice between molded and extruded belts is crucial. Molded belts, like those from Megadyne, are precision-crafted with unique compound formulations, offering exceptional durability and consistency. In contrast, extruded belts are produced through a continuous extrusion process, providing versatility and cost-efficiency while maintaining high-performance standards. Choose the right belt to optimize your power transmission needs.

Printing & Paper Manufacturing

Polyurethane open-end timing belts offer several distinct advantages when it comes to the Printing & Paper Manufacturing industry:

-

Polyurethane belts ensure precise control and synchronization, critical for high-quality printing by minimizing variance in registration and ink placement.

-

Polyurethane's resistance to wear, chemicals, and abrasion significantly extend belt lifespan in the printing and paper manufacturing industry, reducing downtime and maintenance costs.

-

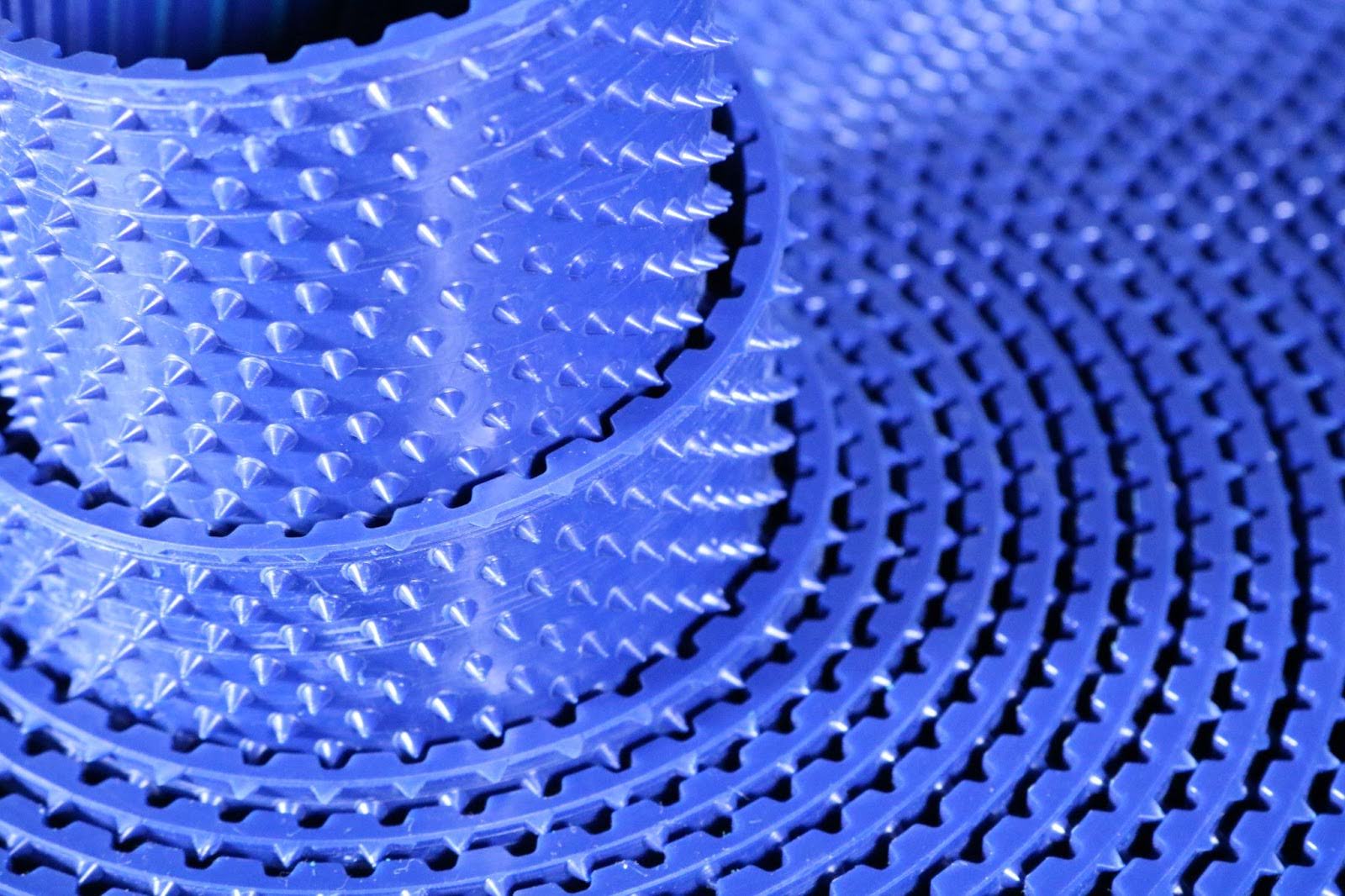

Megalinear belts offer variable shore hardness options, allowing you to choose the ideal hardness for your application, enhancing grip for tasks like paper feeding or improving durability for precise processes like printing and cutting.

-

Customizable covers with different hardness coefficients and abrasion resistance ensure optimal belt performance in specific applications, reducing slippage, maintaining tension, and ensuring reliable operation.

Food & Beverage Manufacturing

Polyurethane open-ended timing belts offer invaluable benefits to the food and beverage industry, particularly in food contact packaging applications. These belts excel in maintaining hygiene and product safety by resisting moisture, chemicals, and wear, which is crucial in environments where contact with food products occurs. Their flexibility and precision facilitate smooth packaging operations, ensuring the efficient and contamination-free handling of food items. Moreover, the durability of polyurethane open-ended timing belts reduces downtime, making them an essential component in food packaging processes that prioritize product integrity and operational efficiency.

In the food and beverage industry, compliance with stringent food contact regulations is paramount. Enter the Megalinear FC belt, purpose-built to meet these requirements. This belt guarantees hygienic and secure material handling, making it an indispensable component in food processing and packaging, ensuring both safety and efficiency in every step of the process.

Construction

Polyurethane open-ended timing belts provide substantial advantages in the construction industry, especially in applications requiring precise linear positioning:

-

Their robust construction and resistance to abrasion, chemicals, and environmental factors make them exceptionally durable in demanding construction environments.

-

These belts ensure accurate and reliable movement of equipment, enabling precise positioning of heavy loads, scaffolding, and construction materials.

-

Their flexibility and high power transmission capabilities contribute to smoother and more efficient construction processes, reducing the risk of delays and enhancing overall productivity on construction sites.

Megadyne's Polyurethane Open-Ended Timing Belts offer a host of benefits, including durability, resistance to wear, and customizable features to meet specific application requirements. Whether it's for industrial machinery, packaging, or any other industry, these belts provide reliable performance.

Moreover, Megadyne goes the extra mile by offering a 1:1 consultation service, ensuring that customers receive tailored solutions that precisely match their needs. This personalized approach makes Megadyne a trusted partner for businesses seeking efficient, high-quality belt solutions for a wide range of applications.

Megadyne also offers premium rubber synchronous timing belts: Check out the next generation of rubber synchronous belts. Introducing the MEGASYNC™ family, surpassing other premium belt drives on the market today.